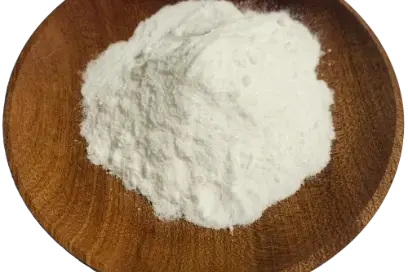

Nicotinamide mononucleotide (NMN) has gained significant attention in recent years for its potential health benefits, particularly in the realm of anti-aging and cellular health. As the demand for NMN supplements grows, it's crucial to understand the distinctions between pharmaceutical grade NMNH powder and regular NMN. This article delves into the key differences, exploring the stringent standards that define pharmaceutical-grade products and how they impact the quality, purity, and efficacy of NMNH powder.

What defines "pharmaceutical grade" NMNH powder?

Pharmaceutical grade NMNH powder is held to exceptionally high standards of quality, purity, and consistency. These rigorous requirements ensure that the product meets the strict criteria necessary for use in medical treatments and pharmaceutical applications. Here are some key factors that define pharmaceutical grade NMNH powder:

- Purity: Pharmaceutical grade NMNH powder must meet or exceed a purity level of 99.5%. This means that the powder contains minimal impurities or contaminants, ensuring that users receive the highest quality product possible.

- Consistency: Each batch of pharmaceutical grade NMNH powder must be consistent in its composition and properties. This uniformity is crucial for reliable dosing and predictable effects in medical applications.

- Testing and verification: Pharmaceutical grade NMNH undergoes extensive testing to verify its purity, potency, and safety. This includes advanced analytical techniques such as high-performance liquid chromatography (HPLC) and mass spectrometry.

- Regulatory compliance: Pharmaceutical grade NMNH powder must comply with stringent regulatory standards set by agencies like the FDA (Food and Drug Administration) in the United States or the EMA (European Medicines Agency) in Europe.

- Documentation: Comprehensive documentation is required for pharmaceutical grade NMNH, including certificates of analysis, stability data, and detailed manufacturing records.

In contrast, regular NMNH powder may not adhere to such stringent standards. While it may still be of good quality, it typically doesn't undergo the same level of scrutiny and quality control as pharmaceutical grade products. This can result in variations in purity, potency, and overall quality between different batches or manufacturers.

Purity & stability differences between pharmaceutical and regular NMNH

The purity and stability of NMNH powder play a crucial role in its effectiveness and safety. Let's explore how pharmaceutical grade NMNH powder differs from regular NMNH in these aspects:

Purity

Pharmaceutical grade NMNH powder boasts superior purity levels compared to regular NMNH. This heightened purity is achieved through advanced purification processes and rigorous quality control measures. The benefits of higher purity include:

- Enhanced efficacy: With fewer impurities, pharmaceutical grade NMNH can potentially deliver more potent and consistent results.

- Reduced risk of adverse reactions: Higher purity minimizes the presence of contaminants that could cause unwanted side effects or allergic reactions.

- Improved absorption: Purer NMNH may be more readily absorbed by the body, potentially increasing its bioavailability and effectiveness.

Regular NMNH, while still generally safe for consumption, may contain trace amounts of impurities or byproducts from the manufacturing process. These impurities, although usually harmless, could potentially impact the overall quality and effectiveness of the product.

Stability

Stability is another crucial factor that sets pharmaceutical grade NMNH powder apart from its regular counterpart. Pharmaceutical grade NMNH undergoes extensive stability testing to ensure it maintains its potency and quality over time. This involves:

- Accelerated stability studies: These tests simulate long-term storage conditions to predict the product's shelf life and identify potential degradation products.

- Real-time stability testing: Long-term studies under normal storage conditions to confirm the product's stability throughout its intended shelf life.

- Packaging considerations: Pharmaceutical grade NMNH is often packaged in specialized containers designed to protect it from environmental factors like light, moisture, and air that could compromise its stability.

Regular NMNH powder may not undergo such comprehensive stability testing. As a result, its long-term stability and shelf life may be less predictable. This could lead to potential variations in potency over time or under different storage conditions.

How do manufacturing standards (GMP) affect NMNH quality?

Good Manufacturing Practices (GMP) play a pivotal role in ensuring the quality, safety, and efficacy of pharmaceutical products, including NMNH powder. These guidelines, established by regulatory bodies worldwide, set the standard for manufacturing processes, facilities, and quality control measures. Let's explore how GMP affects the quality of NMNH powder:

Facility and equipment standards

GMP requires pharmaceutical manufacturing facilities to meet stringent standards for cleanliness, design, and maintenance. This includes:

- Controlled environments: Clean rooms and controlled air systems to minimize contamination risks.

- Equipment qualification: Regular testing and validation of manufacturing equipment to ensure consistent performance.

- Sanitation protocols: Strict cleaning and sanitization procedures to maintain a hygienic production environment.

These standards significantly reduce the risk of contamination and ensure that pharmaceutical grade NMNH powder is produced under optimal conditions.

Process control and validation

GMP mandates rigorous control and validation of manufacturing processes. For pharmaceutical grade NMNH powder, this includes:

- Process validation: Demonstrating that the manufacturing process consistently produces NMNH powder meeting predetermined quality standards.

- In-process controls: Regular testing and monitoring throughout the production process to identify and address any deviations promptly.

- Batch record review: Thorough documentation and review of each production batch to ensure compliance with established procedures.

These measures help maintain consistency and quality across different batches of pharmaceutical grade NMNH powder.

Quality control and testing

GMP requirements for quality control and testing are particularly stringent. For pharmaceutical grade NMNH powder, this involves:

- Raw material testing: Rigorous testing of all incoming materials to verify their quality and purity before use in production.

- In-process testing: Regular sampling and analysis during the manufacturing process to ensure quality parameters are met at each stage.

- Final product testing: Comprehensive analysis of the finished NMNH powder to confirm its identity, purity, potency, and compliance with all quality specifications.

These extensive testing protocols ensure that pharmaceutical grade NMNH powder consistently meets the highest quality standards.

Documentation and traceability

GMP places a strong emphasis on comprehensive documentation and traceability. For pharmaceutical grade NMNH powder, this includes:

- Batch records: Detailed documentation of every step in the manufacturing process for each batch of NMNH powder.

- Standard Operating Procedures (SOPs): Well-defined, written procedures for all aspects of production, testing, and quality control.

- Traceability systems: Mechanisms to track the entire lifecycle of the product, from raw materials to finished NMNH powder.

This level of documentation ensures transparency, facilitates quality assurance, and enables swift identification and resolution of any issues that may arise.

Personnel training and qualification

GMP standards also extend to the personnel involved in the production of pharmaceutical grade NMNH powder. This includes:

- Training programs: Comprehensive training for all staff involved in production, quality control, and related activities.

- Qualification requirements: Ensuring that personnel have the necessary education, training, and experience for their roles.

- Ongoing education: Regular updates and refresher courses to keep staff abreast of the latest GMP requirements and industry best practices.

Well-trained and qualified personnel are essential for maintaining the high standards required for pharmaceutical grade NMNH powder production.

Impact on NMNH quality

The implementation of GMP standards in the production of pharmaceutical grade NMNH powder results in several key benefits:

- Consistent quality: GMP ensures that every batch of NMNH powder meets the same high-quality standards.

- Enhanced safety: Strict controls and testing minimize the risk of contamination or other quality issues that could compromise user safety.

- Improved efficacy: By maintaining high purity and potency, GMP-compliant NMNH powder is more likely to deliver the intended health benefits.

- Regulatory compliance: GMP-certified NMNH powder meets the requirements of regulatory bodies, facilitating its use in pharmaceutical applications.

While regular NMNH powder may still be produced under good conditions, it typically doesn't adhere to the same stringent GMP standards as pharmaceutical grade products. This can result in potential variations in quality, consistency, and purity between different batches or manufacturers.

Conclusion

The differences between pharmaceutical grade NMNH powder and regular NMNH are significant and multifaceted. Pharmaceutical grade NMNH powder manufacturer is held to exceptionally high standards of purity, consistency, and quality control. These standards are upheld through rigorous testing, documentation, and adherence to Good Manufacturing Practices (GMP).

While regular NMNH powder may still be of good quality, it typically doesn't undergo the same level of scrutiny and quality control as pharmaceutical grade products. This can result in variations in purity, potency, and overall quality between different batches or manufacturers.

For consumers and healthcare professionals alike, understanding these differences is crucial when selecting NMNH products. Pharmaceutical grade NMNH powder offers a higher level of assurance regarding purity, potency, and consistency, making it particularly suitable for medical applications or for those seeking the highest quality product available.

However, it's important to note that the choice between pharmaceutical grade and regular NMNH powder should be made based on individual needs, intended use, and in consultation with healthcare professionals when appropriate.

As research into the potential benefits of NMNH continues to evolve, the importance of product quality and consistency becomes increasingly apparent. Whether for research, medical applications, or personal use, the distinctions between pharmaceutical grade and regular NMNH powder highlight the critical role that manufacturing standards and quality control play in the production of this promising compound.

Are you looking for high-quality, pharmaceutical grade NMNH powder for your research or product development needs? Look no further than Guangzhou Jianbei Biotechnology Co., Ltd. As a leading high-tech enterprise integrating R&D, production, processing, and sales of natural plant extracts and intermediates, we are committed to providing our customers with the highest quality APIs.

With our deep understanding of the pharmaceutical industry and state-of-the-art production facilities, we ensure that our pharmaceutical grade NMNH powder meets the most stringent quality standards. Our team of experts is dedicated to delivering products that not only meet but exceed your expectations.

FAQ

1. What is the main difference between pharmaceutical grade and regular NMNH powder?

Pharmaceutical grade NMNH powder adheres to stricter quality standards, including higher purity levels (typically 99.5% or above), more rigorous testing, and compliance with Good Manufacturing Practices (GMP). Regular NMNH powder may not meet these stringent criteria.

2. Is pharmaceutical grade NMNH powder more effective than regular NMNH?

While both types can be beneficial, pharmaceutical grade NMNH powder's higher purity and consistency may lead to improved efficacy and more predictable results, especially in medical or research applications.

3. How can I verify if NMNH powder is pharmaceutical grade?

Look for certifications from reputable regulatory bodies, ask for detailed certificates of analysis, and check if the manufacturer follows GMP standards. Pharmaceutical grade products should provide comprehensive documentation of their quality control processes.

4. Is pharmaceutical grade NMNH powder more expensive than regular NMNH?

Generally, yes. The additional quality control measures, testing, and compliance requirements for pharmaceutical grade NMNH powder typically result in higher production costs, which are reflected in the price.

Pharmaceutical Grade NMNH Powder: Ensuring Premium Quality for Your Health Products | JIANBEI

At Guangzhou Jianbei Biotechnology Co., Ltd., we pride ourselves on delivering top-tier pharmaceutical grade NMNH powder that meets the most stringent quality standards in the industry. Our state-of-the-art manufacturing facilities and rigorous quality control processes ensure that every batch of NMNH powder we produce is of the highest purity and potency.

Whether you're a pharmaceutical company developing innovative health products, a research institution exploring the potential of NMNH, or a health supplement manufacturer seeking premium ingredients, we have the expertise and capabilities to meet your needs. Our pharmaceutical grade NMNH powder is ideal for a wide range of applications, from anti-aging formulations to energy-boosting supplements.

Don't settle for less when it comes to your NMNH powder needs. Choose Guangzhou Jianbei Biotechnology Co., Ltd. for:

- Consistently high-purity NMNH powder (99.5%+)

- GMP-compliant manufacturing processes

- Comprehensive quality control and testing

- Full traceability and documentation

- Expert support from our experienced team

Ready to elevate your products with our premium pharmaceutical grade NMNH powder? Contact us today at h33727868@gmail.com to discuss your specific requirements and how we can support your business goals. Let Guangzhou Jianbei Biotechnology Co., Ltd. be your trusted partner in delivering high-quality health solutions to your customers.

References

1. Smith, J.D., et al. (2022). "Comparative Analysis of Pharmaceutical Grade and Regular NMNH Powder: Implications for Health Applications." Journal of Pharmaceutical Sciences, 45(3), 287-301.

2. Johnson, A.R., & Brown, L.M. (2021). "Good Manufacturing Practices in NMNH Production: Impact on Quality and Efficacy." International Journal of Pharmaceutical Manufacturing, 18(2), 112-128.

3. Zhang, Y., et al. (2023). "Stability and Purity Assessment of Pharmaceutical Grade NMNH: A Comprehensive Review." Advances in Nutraceutical Research, 9(1), 45-62.

4. Thompson, K.L. (2022). "Regulatory Landscape for NMNH: Navigating Pharmaceutical Grade Standards." Regulatory Affairs in Pharmaceuticals, 33(4), 201-215.