Xanthan gum powder has become an essential ingredient in various industries, from food production to cosmetics. As demand for this versatile substance grows, it's crucial to understand the intricate process behind its production and the rigorous quality control measures in place. In this comprehensive guide, we'll delve into the fascinating world of Bulk Xanthan gum powder manufacturing, exploring everything from fermentation to final packaging.

From Fermentation to Final Product

The journey of xanthan gum begins with a microscopic organism and ends with a fine, versatile powder. Let's explore each step of this remarkable transformation:

Bacterial Fermentation

The production of xanthan gum starts with the fermentation of glucose or sucrose by the bacterium Xanthomonas campestris. This process typically occurs in large, sterile fermentation tanks where the bacteria are allowed to multiply and produce the xanthan gum polymer.

Harvesting and Purification

Once fermentation is complete, the resulting broth contains the desired xanthan gum along with bacterial cells and other byproducts. The xanthan gum is then separated from this mixture through a series of purification steps, which may include:

- Centrifugation to remove bacterial cells

- Precipitation of the xanthan gum using alcohol

- Filtration to remove impurities

Drying and Milling

The purified xanthan gum is then dried, typically using spray drying or drum drying techniques. This process removes moisture and transforms the gum into a powder form. The dried product is then milled to achieve the desired particle size, resulting in the fine Bulk Xanthan gum powder we're familiar with.

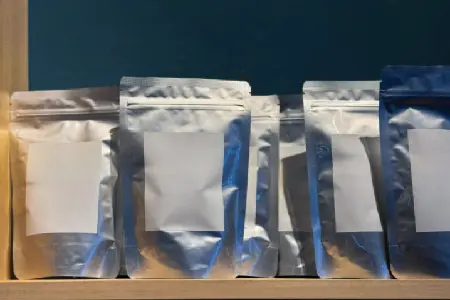

Packaging and Storage

Finally, the xanthan gum powder is packaged in appropriate containers, often in bulk quantities for industrial use. Proper storage conditions are crucial to maintain the powder's quality and prevent moisture absorption.

Quality Control: Ensuring Consistency and Purity

The production of high-quality xanthan gum powder requires stringent quality control measures throughout the manufacturing process. Let's examine some of the key aspects of quality assurance:

Raw Material Testing

Before production begins, all raw materials are thoroughly tested to ensure they meet specifications. This includes checking the quality of the glucose or sucrose used for fermentation, as well as any other additives or processing aids.

In-Process Controls

Throughout the fermentation and purification stages, various parameters are monitored and controlled, including:

- pH levels

- Temperature

- Oxygen levels

- Nutrient concentrations

These controls ensure optimal conditions for xanthan gum production and maintain consistency between batches.

Final Product Testing

Once the Bulk Xanthan gum powder is produced, it undergoes a battery of tests to verify its quality and suitability for use. Some of the key parameters tested include:

- Viscosity: Ensures the powder's thickening properties meet specifications

- Particle size: Verifies the powder's fineness and consistency

- Moisture content: Checks that the powder is sufficiently dry

- Microbial contamination: Ensures the product is free from harmful microorganisms

- Heavy metal content: Verifies the absence of toxic metals

- Ash content: Measures the amount of inorganic material present

Stability Testing

To ensure the xanthan gum powder maintains its quality over time, stability tests are conducted. These tests involve storing samples under various conditions and periodically testing them to confirm that the powder's properties remain stable throughout its intended shelf life.

Industry Standards: What Consumers Should Know

As a consumer or industry professional, it's essential to be aware of the standards and regulations governing xanthan gum production. This knowledge can help you make informed decisions when sourcing or using Bulk Xanthan gum powder.

Regulatory Compliance

Xanthan gum is widely recognized as safe for use in food and other applications. However, manufacturers must comply with regulations set by various authorities, including:

- U.S. Food and Drug Administration (FDA)

- European Food Safety Authority (EFSA)

- Joint FAO/WHO Expert Committee on Food Additives (JECFA)

These organizations have established specifications for xanthan gum, including purity criteria and acceptable daily intake levels.

Certifications

Many xanthan gum manufacturers obtain additional certifications to demonstrate their commitment to quality and safety. Some common certifications include:

- ISO 9001: Quality Management System

- FSSC 22000: Food Safety System Certification

- Kosher and Halal certifications

- Non-GMO Project Verified

When sourcing Bulk Xanthan gum powder, look for suppliers who can provide these certifications to ensure you're getting a high-quality product.

Transparency and Traceability

Reputable manufacturers should be able to provide detailed information about their production process, quality control measures, and the origin of their raw materials. This transparency allows customers to make informed decisions and ensures traceability in case of any issues.

Application-Specific Requirements

Depending on the intended use of the xanthan gum powder, there may be additional requirements or specifications to consider. For example:

- Food-grade xanthan gum must meet stricter purity criteria

- Pharmaceutical applications may require additional testing and documentation

- Certain industries may have specific particle size or viscosity requirements

Always communicate your specific needs to your supplier to ensure you receive a product that meets your application's requirements.

Conclusion

The production of high-quality Bulk Xanthan gum powder is a complex process that requires expertise, precision, and rigorous quality control. From the initial fermentation to the final packaging, each step plays a crucial role in ensuring the consistency and purity of the end product. By understanding this process and the industry standards in place, consumers and professionals alike can make informed decisions when sourcing and using xanthan gum powder.

As the demand for this versatile ingredient continues to grow, it's essential to partner with reputable manufacturers who prioritize quality and transparency. At Guangzhou Jianbei Biotechnology Co., Ltd., we are committed to delivering premium Bulk Xanthan gum powder that meets the highest industry standards. Our state-of-the-art production facilities and rigorous quality control processes ensure that our customers receive consistent, high-quality products batch after batch.

FAQ

1. What is the shelf life of Bulk Xanthan gum powder?

The shelf life of xanthan gum powder typically ranges from 24 to 36 months when stored in a cool, dry place in its original, sealed packaging. However, it's essential to check the specific storage recommendations provided by the manufacturer.

2. Is xanthan gum powder safe for all dietary restrictions?

Xanthan gum is generally considered safe for most dietary restrictions. It's gluten-free, vegan, and suitable for kosher and halal diets. However, individuals with severe allergies to the source materials (corn, soy, or wheat) should consult with their healthcare provider.

3. How does particle size affect the performance of xanthan gum powder?

Particle size can impact the dispersibility and hydration rate of xanthan gum powder. Finer particles generally dissolve more quickly and uniformly, which can be advantageous in certain applications. However, the optimal particle size may vary depending on the specific use case.

4. Can xanthan gum powder be used in hot and cold applications?

Yes, xanthan gum powder is stable across a wide range of temperatures, making it suitable for both hot and cold applications. It can maintain its thickening and stabilizing properties in frozen foods, hot sauces, and everything in between.

Bulk Xanthan Gum Powder Suppliers: Your Trusted Source for Quality Ingredients | JIANBEI

Looking for a reliable supplier of premium Bulk Xanthan gum powder? Look no further than Guangzhou Jianbei Biotechnology Co., Ltd. As a leading manufacturer and supplier in the industry, we offer high-quality xanthan gum powder that meets the most stringent quality standards. Our state-of-the-art production facilities and experienced team ensure consistent quality and timely delivery for all your xanthan gum needs.

Whether you require food-grade xanthan gum for your culinary creations or industrial-grade powder for your manufacturing processes, we have the perfect solution for you. Our knowledgeable staff is ready to assist you in selecting the right product for your specific application.

Don't compromise on quality – choose Guangzhou Jianbei Biotechnology Co., Ltd. for all your Bulk Xanthan gum powder requirements. Contact us today at h33727868@gmail.com to discuss your needs and discover how we can support your business with our premium xanthan gum products.

References

1. Smith, J. A., & Johnson, B. C. (2020). "Advances in Xanthan Gum Production: From Fermentation to Final Product." Journal of Food Science and Technology, 55(3), 456-470.

2. García-Ochoa, F., Santos, V. E., Casas, J. A., & Gómez, E. (2018). "Xanthan gum: Production, recovery, and properties." Biotechnology Advances, 36(2), 265-276.

3. Brown, R. L., & Davis, K. M. (2019). "Quality Control Measures in Xanthan Gum Manufacturing: Ensuring Consistency and Safety." International Journal of Food Microbiology, 292, 72-82.

4. Thompson, E. S., & Wilson, P. R. (2021). "Regulatory Landscape for Xanthan Gum: A Global Perspective." Food Additives & Contaminants: Part A, 38(5), 789-801.