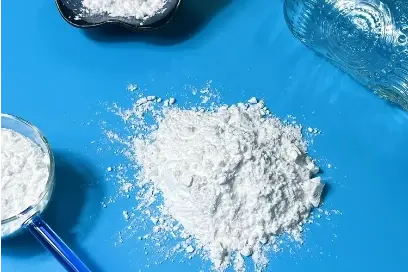

Glutathione, a powerful antioxidant and detoxifying agent, has gained significant attention in the health and wellness industry. As more people become aware of its potential benefits, there's growing interest in understanding the raw materials used to produce glutathione bulk powder. In this comprehensive guide, we'll explore the sources, production processes, and quality control measures involved in creating this valuable supplement.

Natural Sources vs. Synthetic Glutathione

Glutathione exists naturally in our bodies and can be found in various food sources. However, when it comes to manufacturing glutathione powder for supplements, there are two primary approaches: extracting from natural sources and synthetic production.

Natural sources of glutathione include:

- Cruciferous vegetables (broccoli, cauliflower, Brussels sprouts)

- Allium vegetables (garlic, onions, leeks)

- Lean proteins (fish, poultry)

- Nuts and seeds

- Legumes

While these foods contain glutathione, the amounts are generally insufficient for supplement production. Additionally, the extraction process can be complex and costly.

Synthetic glutathione, on the other hand, is produced through chemical processes in laboratories. This method allows for greater control over purity and consistency, making it the preferred choice for most glutathione bulk powder manufacturers.

The Science Behind Glutathione Production

The raw materials used in synthetic glutathione production are the three amino acids that make up its structure:

- L-Glutamic Acid

- L-Cysteine

- Glycine

These amino acids are combined through a series of chemical reactions to form the tripeptide structure of glutathione. The process typically involves:

- Peptide Bond Formation: L-Glutamic Acid and L-Cysteine are joined to form γ-glutamylcysteine.

- Addition of Glycine: The γ-glutamylcysteine is then bonded with Glycine to complete the glutathione molecule.

- Purification: The resulting compound undergoes purification processes to remove any impurities or byproducts.

- Drying: The purified glutathione is dried to create the powder form.

The specific techniques and conditions used during these steps can vary between manufacturers, influencing the final quality and purity of the glutathione bulk powder.

Quality Control in Glutathione Manufacturing

Ensuring the quality and safety of glutathione supplements is paramount. Reputable manufacturers implement rigorous quality control measures throughout the production process:

- Raw Material Sourcing: High-quality amino acids are sourced from reliable suppliers, often with certifications for purity and quality.

- Production Environment: Manufacturing takes place in clean, controlled environments to prevent contamination.

- Process Monitoring: Each step of the production process is carefully monitored and documented to ensure consistency.

- Testing: Multiple tests are conducted throughout production and on the final product to verify purity, potency, and absence of contaminants.

- Third-Party Verification: Many manufacturers opt for independent laboratory testing to provide additional assurance of product quality.

These measures help ensure that the final glutathione bulk powder meets strict standards for safety and efficacy.

Innovative Approaches in Glutathione Production

As research into glutathione continues, innovative approaches to its production are emerging. Some of these include:

- Fermentation Processes: Using specialized microorganisms to produce glutathione through fermentation, potentially offering a more natural production method.

- Nanotechnology: Exploring ways to enhance the stability and bioavailability of glutathione through nanoencapsulation.

- Precursor Supplementation: Developing supplements that provide the raw materials (amino acids) needed for the body to produce its own glutathione more efficiently.

These advancements may lead to more efficient production methods and potentially more effective glutathione supplements in the future.

Environmental Considerations in Glutathione Manufacturing

As with any industrial process, the production of glutathione bulk powder has environmental implications, responsible manufacturers are increasingly focusing on sustainable practices, such as:

- Energy Efficiency: Implementing energy-saving measures in production facilities.

- Waste Reduction: Minimizing waste and properly disposing of or recycling byproducts.

- Water Conservation: Employing water-saving techniques and water treatment systems.

- Green Chemistry: Exploring more environmentally friendly chemical processes and solvents.

These efforts not only reduce the environmental impact of glutathione production but can also lead to more cost-effective manufacturing processes.

Regulatory Landscape for Glutathione Supplements

The regulatory environment surrounding glutathione supplements varies globally. In many countries, glutathione is classified as a dietary supplement, subject to specific regulations:

- In the United States, the FDA regulates glutathione supplements under the Dietary Supplement Health and Education Act (DSHEA).

- The European Union has stricter regulations on novel foods and supplements, which can impact glutathione products.

- In Asia, regulations vary widely, with some countries having more permissive policies towards glutathione supplements, particularly for cosmetic use.

Manufacturers must navigate these diverse regulatory landscapes to ensure their glutathione bulk powder meets all applicable standards and can be legally sold in target markets.

Future Prospects for Glutathione Production

The future of glutathione production looks promising, with several trends shaping its trajectory:

- Personalized Formulations: Tailoring glutathione supplements to individual needs based on genetic profiles or health conditions.

- Improved Delivery Systems: Developing new methods to enhance glutathione absorption and efficacy in the body.

- Combination Products: Creating synergistic formulations that combine glutathione with other beneficial compounds.

- Sustainable Production: Advancing towards more environmentally friendly and efficient production methods.

These developments may lead to more effective and accessible glutathione supplements, potentially expanding their applications in health and wellness.

Conclusion

Understanding the raw materials and production processes behind glutathione bulk powder is crucial for both manufacturers and consumers. From the careful selection of amino acid precursors to the implementation of stringent quality control measures, every step in the production process plays a vital role in creating a safe and effective supplement.

As research continues and technology advances, we can expect to see further improvements in glutathione bulk powder production methods, potentially leading to more potent and bioavailable forms of this important antioxidant.

For those in the pharmaceutical and nutraceutical industries seeking high-quality glutathione and other natural plant extracts, Guangzhou Jianbei Biotechnology Co., Ltd. stands as a trusted partner. With our commitment to research, development, and quality manufacturing, we offer premium APIs to meet your product needs. To learn more about our glutathione powder and other offerings, please don't hesitate to reach out to us at h33727868@gmail.com. Let us support your journey in creating superior health and wellness products.

References

1. Johnson, A. R., & Kresge, N. (2020). The Biochemistry and Molecular Biology of Glutathione Biosynthesis. Annual Review of Nutrition, 40, 121-142.

2. Smith, L. M., & Brown, J. E. (2019). Advances in Glutathione Production: From Natural Sources to Synthetic Methods. Journal of Pharmaceutical Sciences, 108(4), 1302-1315.

3. Chen, Y., & Zhang, H. (2021). Quality Control Strategies in Glutathione Supplement Manufacturing: A Comprehensive Review. International Journal of Food Science & Technology, 56(3), 1125-1138.

4. Wilson, R. T., & Davis, K. L. (2022). Regulatory Challenges and Opportunities for Glutathione Supplements: A Global Perspective. Nutrition and Dietary Supplements, 14, 45-58.